The Challenge of Unstable Fill Levels

In modern manufacturing, bottling lines run at incredible speeds. A small variation in liquid level can cause underfilling, overfilling, or even product rejection. These bottling defects lead to wasted resources, compliance issues, and unhappy customers. Traditional inspection methods often miss subtle changes, but advanced fill-level sensors ensure consistent accuracy and help manufacturers avoid costly inefficiencies.

The Role of Fill-Level Sensors

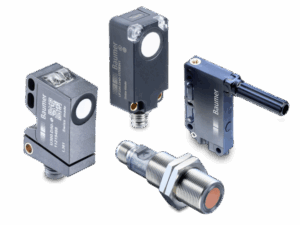

This is where fill-level sensors step in. By providing non-contact, high-precision measurements, they ensure that every bottle, vial, or container is filled exactly to specification. Unlike manual checks or basic mechanical sensors, advanced systems like the Baumer Nivotester use precision sensing to detect even the smallest deviation in fill levels.

For production managers, this means consistent quality and fewer line stoppages. For operators, it reduces rework and increases confidence in the process.

Smarter Monitoring with IO-Link

One of the biggest advantages today is IO-Link integration. With this digital communication standard, fill-level sensors can send detailed real-time data directly to control systems. Instead of just pass/fail signals, operators gain actionable insights – such as early warnings about drift, contamination, or machine wear.

This transforms bottling from a reactive process into a proactive one, where adjustments happen before defects occur.

Benefits of Using Advanced Fill-Level Sensors

-

Defect Reduction: Precise detection eliminates overfilled or underfilled bottles.

-

Cost Savings: Less product waste and fewer rejected batches.

-

Higher Uptime: Smart diagnostics help prevent unplanned downtime.

-

Compliance Assurance: Consistent fill levels meet strict regulatory standards.

Why Partner with Omkar Systems

As an authorized distributor of Baumer products, Omkar Systems brings expertise in deploying the right sensor solutions for complex manufacturing environments. Our team supports everything from product selection to integration, ensuring manufacturers get the full benefit of fill-level sensors and IO-Link connectivity.

Final Word

In a competitive industry where quality and efficiency define success, advanced fill-level sensors are no longer optional – they are essential. Manufacturers who adopt them see measurable improvements in productivity, consistency, and customer trust.

If you’re looking to solve fill-level instability or bottling defects, now is the time to explore smarter sensing solutions with Omkar Systems.